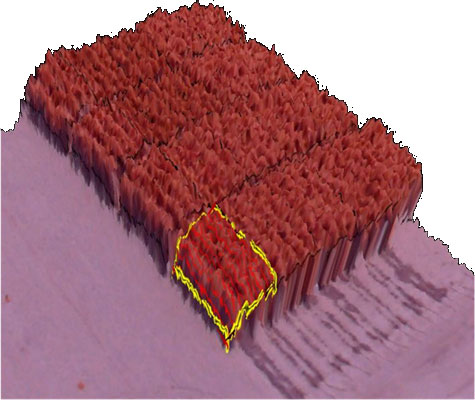

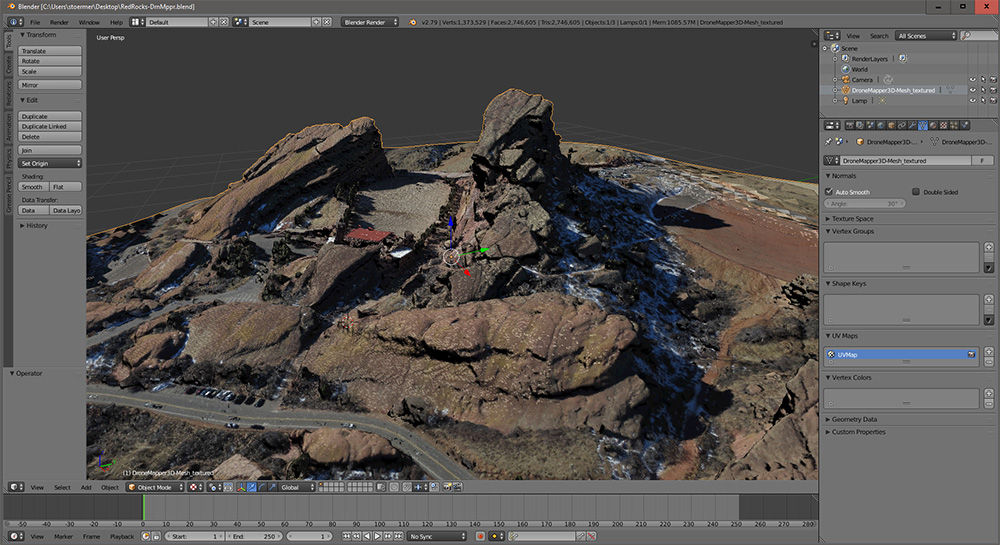

We’ve updated our sample page to include a Blender project with the high resolution Red Rocks virtual reality scene. We’ve also added a download link to the .OBJ, .MTL and .PLY files for import into Unity3D or other 3D rendering software. Creating real world scenes in VR quickly from drone imagery is possible using an oblique collection and our processing software.

The image above shows a 3D Textured Mesh Point Cloud converted to .OBJ format displayed in Blender. The .OBJ has an associated .MTL and .JPG file to provide the texture and material mapping.

download processed products in .OBJ

download processed products in .PLY

download Blender 3D project

We’d love to see how you use this data in your own projects! Let us know